ABOUT

US

WHY TITAN CLIMBING STARTED

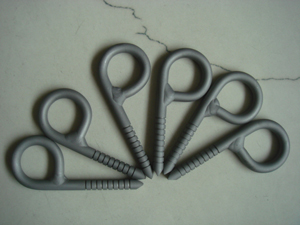

Experienced climber Martin Roberts started producing titanium bolts in 2009 when he wanted to develop and bolt his own routes in Thailand. Astonished by how expensive titanium bolts were at the time he chose to find a very direct path in producing the finest, long lasting solution to safely bolt new routes and re-bolt existing routes. Initially bolts were produced in China in order to provide a fast, cost effective solution to the ongoing danger of falling climbers regularly breaking stainless steel bolts. A great deal of testing was carried out and safe titanium bolts at a good price were produced.

Even without any advertising, demand grew quickly and word of these new, superior climbing bolts soon spread and it wasn’t long before Martin was receiving orders from individuals and organisations throughout The Americas, The Far East, Australia, Europe and beyond. These climbers had visited crags all around the world and it was clear to them that many stainless steel bolts were rusting, missing or broken. Many crags had already been rebolted once or twice, and in the case of Thailand, many times.

TITAN CLIMBING TODAY

In 2013 the decision was made to move the manufacturing facility to Martin’s native Sheffield, England, a city renowned worldwide for its expertise in producing high quality metal products. Our manufacturing operation here helps support the local community and this latest move means Martin, who still heads up the company, can oversee every stage of the production process, and this in addition to direct sales, has allowed the company to offer titanium climbing bolts at a price comparable to stainless steel.

As of this year, have delivered equipment to 39 countries on 6 continents.

A bolting revolution has begun!

Quality Control

A strict quality control program is followed throughout the whole process from material sourcing, all the way through manufacture and destructive / non destructive testing.

Rigorous in-house testing meets or exceeds the requirements of EN959 and all bolts and anchors are certified to EN959. All bolts and anchors are also 100% inspected and passivated to ASTM B600-11 to ensure no iron contamination is on the surface of the titanium.

In 2016 we had all our bolts and anchors tested by SATRA, an external test house in UK to both EN959 and UIAA123.

You may notice a slight indentation on the inside of the bolt eyes or the rings. That’s evidence of the fact that every product is proof loaded before it leaves us.

© Copyright Titan Climbing 2013-. All rights reserved.